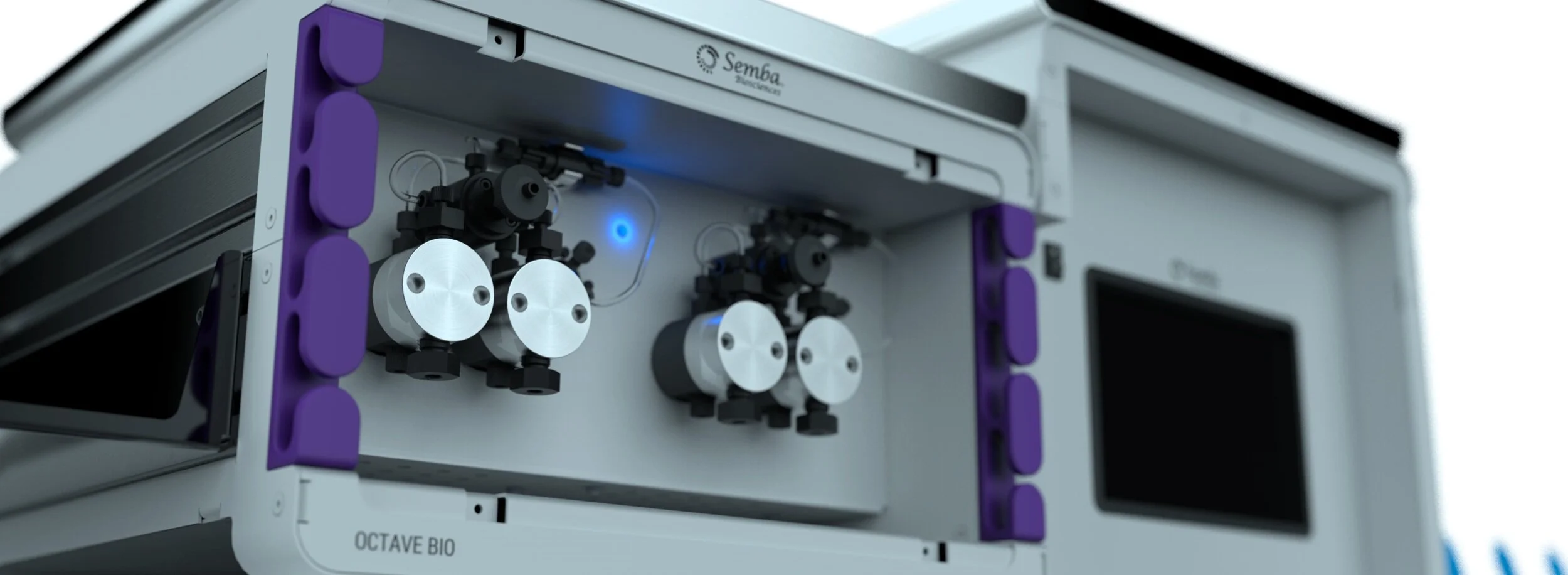

Semba Octave is an automated liquid continuous chromatography platform designed for preparative-scale purification of chemical and biological compounds. With its small footprint and modular design, the Octave System brings the high resolution and efficiency of SMBC to the bench top, packing more purification capability into this space than any other similar-size instrument.

Design Research

Every project involves multiple engagements with research. Whether observatory, contextual, qualitative, quantitative, analog, or digital, information to the use and user are key to creating successful outcomes.

With the Octave, seeing how the product was used, stored, and interacted with in the field of use was crucial to knowing what behaviors and needs to design for. Details such as cord management, interaction points, and functional layout were among the major improvements we were able to make for the user.

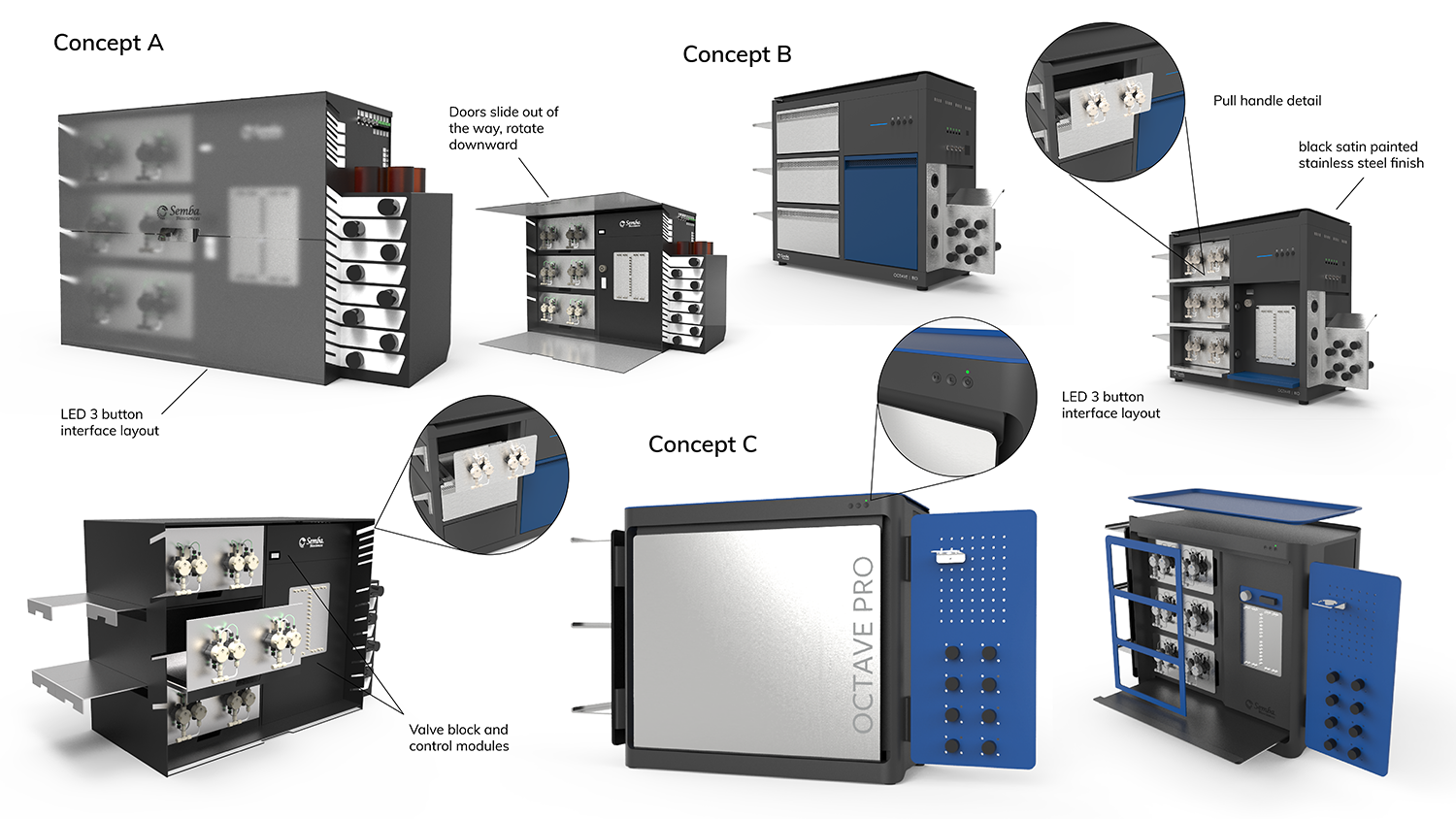

Industrial Design

Our designers visualize the possibilities on different levels of interaction, assembly, aesthetics, and ergonomics. Visualization is our way of facilitating a conversation between all stakeholders that arrives at a consensus of accomplishment.

Mechanical Engineering

Our mechanical engineers help evaluate the manufacture and assembly of our designs to ensure they accomplish the product goals. In CAD we develop manufacturable solutions considering cost, assembly, and accurate geometry to reflect functional and desirable needs for the products.

Electrical Engineering

We have a high level capability to integrate the control and regulation of product capabilities through the work of electrical engineers with the rest of our development team.

Industrial Design

With the Octave we desired to present the successfully functional product in a way that is contextually desirable by both primary and secondary users. The material choices, colors, placement of interactive elements, branding, and product use graphics are all an integral part of design application.